PID Terminology 2

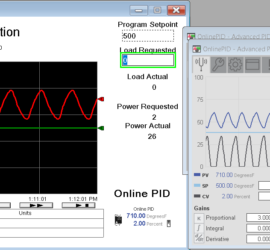

Introduction to PID Terminology PID Terminology is essential to understanding how PID works. For this reason, we’ll go through various terms you will see when reading about PID. In short, PID itself stands for Proportional, Integral, and Derivative. Basically, the purpose of PID is to hold analog values at a Read More »