Introduction to Seal Circuits

Seals and latches allow you to momentary press a button to energize an output. The output stays on until you press another button to shut the output off. There are some dangers associated with the latches that we will also discuss. If you are not familiar with basic ladder logic, please read this post before continuing.

Seals

When I think of seals, I think of a standard motor starter circuit on a schematic. There is one button to start the motor, and another button to stop the motor. You logic might vary depending on how you wire the switches. In this case, just for clarification in logic, we will assume that both the start and stop buttons are normally open.

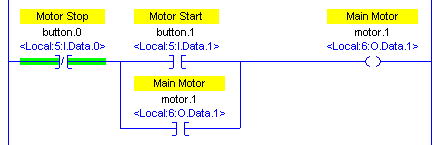

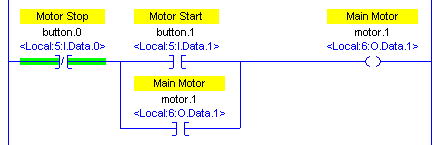

Let’s take a look at a basic seal in ladder logic. Remember, the instructions are just part of the PLC Program. In no way do the instructions reflect if the switch itself is normally open, or normally shut. The Examine Off instruction is true when there is a zero on button.0’s tag. On the other hand, the Examine On instruction is true when you press button.1.

Description of Operation

First, let’s convert this logic into plain English: If we are NOT stopping the motor, AND (the operator presses the start button OR the motor is already running) then the output is energized.

Once the start button is pressed, the output will come on. Since the XIC below the start button is looking at the output, it will go true as well. Once the operator releases the start button, we still have logical continuity. When the operator presses the stop button, there is no longer logical continuity to the output, so motor.1 will shut off. Therefore, the XIC instruction for motor.1 will no longer be true. When the operator releases the stop button, button.0 will have logical continuity again, but there is no path for the output to energize. When the operator presses the start button again, motor.1 is energizes. The output will seal.

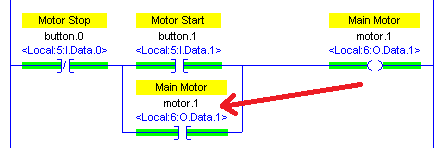

Let’s look at what happens when the operator presses the start button:

Now, let’s see what happens when the operator releases the start button:

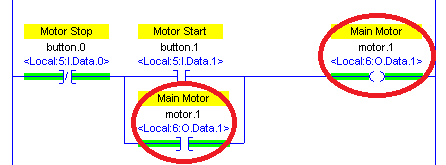

You can see that even though the operator released the start button, there is still a path for the output to remain energized. Next, let’s see what happens when the operator presses the STOP button.

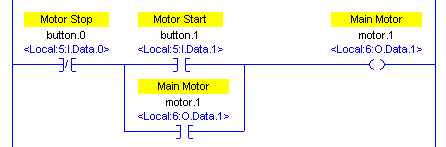

When the operator presses the stop button, the first instruction is no longer true. Therefore, the output shuts off, and the seal breaks. When the operator lets up on the stop button, there is still no path for the output to come on again. The output will remain off until the operator presses the start button again.

Summary of Seal Circuits

We can use seal logic whenever we have a momentary input that we need to hold. A separate condition will break that seal. Keep in mind there is a major difference between a seal and a latch. The seal circuit will drop out when the processor goes back into run mode. In other words, if you loose power, and power comes back, the seal will drop out. On the other hand, the latch instruction is retentive.

If you have permissives, you can add them immediately after the start condition within the branch. Permissives must be made before the output can energize the first time. After that, permissives can drop out, and the seal remains. Interlocks on the other hand, can be immediately after the stop condition (outside of the branch), for example. When we loose an interlock condition, we want to break the seal, and prevent the output from energizing.

For more posts, visit the ControlLogix category page!

— Ricky Bryce

Pingback: ControlLogix restart lockout logic using the TON instruction.