Introduction to the SLC-500 Custom Data Monitor

The SLC-500 Custom Data Monitor allows you to monitor data from different places in the project all in one place. In this post, I’ll discuss how to use the custom data monitor. When you troubleshoot your equipment, normally, you look for an output address in the program. Then, navigate through the project to find the reason the output did not energize. With the Custom Data Monitor, you can just build a list of conditions that need to be met for an output to energize. The next time the output will not energize, simply open the data monitor to see what condition is not satisfied, then fix that condition! You can define up to 255 Custom Data Monitors in a project.

Example Scenario

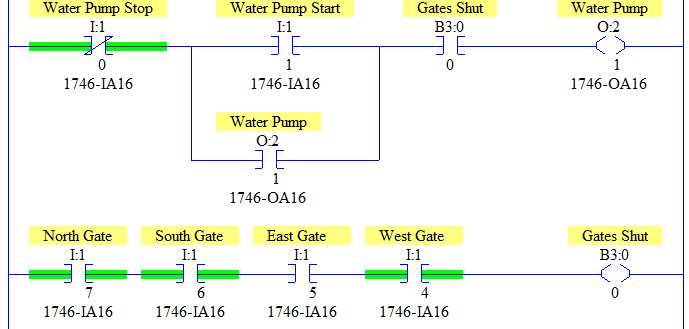

At this time, look at the example scenario.

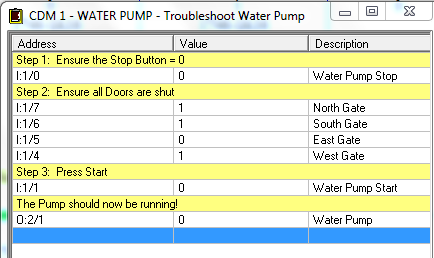

Here, we have a Water Pump that will not energize. Although this is a very simple problem, it will act as a good example on how to set up the CDM. You clearly see the reason for the failure is the East Gate. Once we shut the East Gate, the operator will press the start button. The pump will then run. To find the failure normally, though, you need to locate the output, and navigate the logic. We will create a CDM to make our job easier to find the problem next time.

Create the CDM

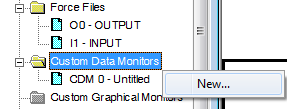

To create the CDM, Right-Click the Custom Data Monitor folder in the project tree, and select “New”.

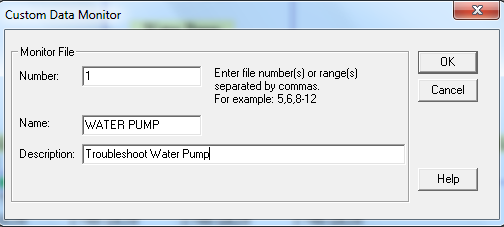

Secondly, name the CDM, and give it a description. Press OK.

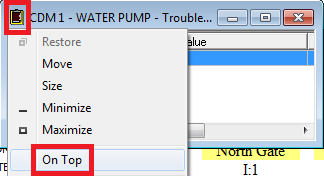

Next, open the CDM from the project tree. The problem is that if we try to navigate logic with the CDM open, the logic window will cover up part of our CMD. We can fix this by clicking the clipboard icon in the upper left corner of the CDM, and choose “On Top”.

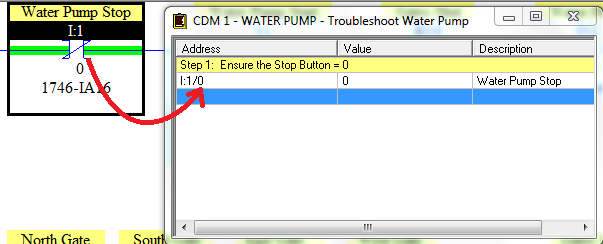

Thirdly, I’ll type some text in the first line of the CDM as shown, then drag the stop button from logic.

Similarly, we’ll create the other steps as follows:

Close the CDM, and Save your work! You now have a Custom Data Monitor to troubleshoot the Main water pump next time it will not run.

Summary

Remember you can create up to 255 different CDM files. Use these for different purposes such as troubleshooting, displaying analog values of your equipment, or the current step number during a startup sequence. As long as you are online, the data should be updating in real time.

For more information on the SLC-500, visit the Category Page!

For other information on the CDM, visit Rockwell’s Web Page.

— Ricky Bryce