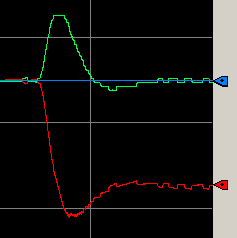

PIDE Stuck High or Low

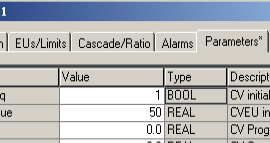

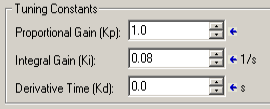

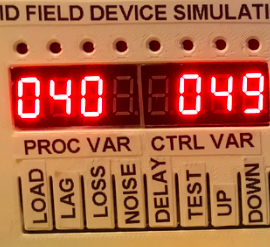

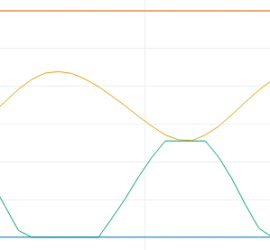

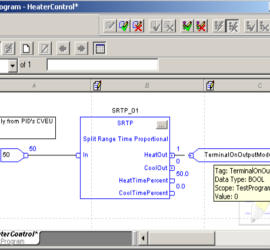

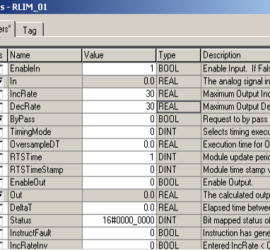

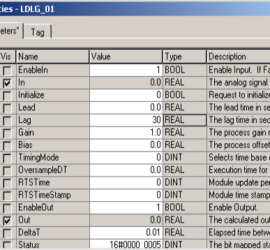

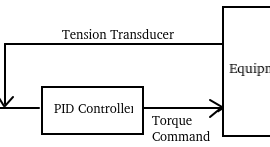

How to fix PIDE Stuck High or Low in ControlLogix Using Function Blocks in ControlLogix, you can get the PIDE Stuck High or Low. This can occur when you are tuning a loop. To begin with, you only have proportional gain when tuning the loop. Your Process Variable could be Read More »