Introduction to PLC-5 Structure

The PLC-5 Structure was probably the most common Allen Bradley processors in the Industry. Produced in the 1980’s, this processor began to replace the PLC-2. Many industrial sites still widely use the PLC-5 processor. However, these remaining PLC-5 processors are slowly being replaced by the new ControlLogix platform. This is the newest Allen-Bradley industrial automation system (as of this date). It’s purpose is to automate the control of equipment. In this PLC-5 Structure Overview, we will discuss it’s memory layout, software, and communication protocols.

The PLC-5 is a 16 bit processor. This means that most everything is based on 16 bit integers, such as the whole numbers that you store. Also the I/O (Input and Output addressing). Please remember that in this processor, the I/O is all addressed in OCTAL.

In the early days, you programmed the PLC-5 using DOS based software, such as 6200, or AI. The most common software we use now is RSLogix 5. RSLogix 5 uses RSLinx as the communication server. Once you configure RSLinx, use RSLogix to go online with the processor. Versions existed for every major Windows operating system from Windows 95 up to Windows 10.

Memory Structure

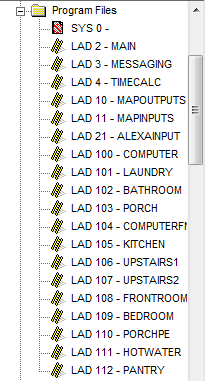

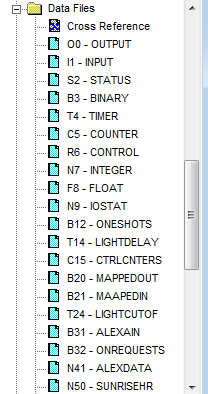

The PLC-5 has two main divisions of memory: Data Files, and Program files. Data files store the data (data registers). Program files read and manipulate the data using Ladder logic. Some PLC-5 processors also supported structured text programming.

Communication

The older processors (original platform) support Data Highway Plus (DH+) and Remote I/O protocols. The newer (enhanced) series of processors also support RS232, RS422, or RS423 communication. You can obtain communication using an RS232 Null Modem cable.

You can also purchase enhanced processors that will perform communication to ControlNet and Ethernet. Here is an image of a standard enhanced processor.

This particular processor has three communication channels. Channel 1 is on the bottom left. This supports both Remote I/O and DH+ Communications. Communication Channel 2 is usually not configured by default, but will also support DH+ and Remote I/O.

We usually use Channel 0 for RS232. However we have the option to configure it for RS422 or RS423.

Both the orignal and enhanced processors use Lithium batteries. This will store the project in the event of a power outage.

The key switch sets the mode of the processor. In run mode, you cannot change the program structure. (ie: Download or Online edits). In program mode, the processor does not execute the logic. When the processor is in Remote “REM” mode, you will change the mode of the processor from the software.

Even though the PLC-5 is obsolete, you will find it’s still automating a lot of industrial equipment. Parts for this system are widely available on various websites. If you can obtain a licensed copy of the software, this system is a great learning tool.

I will continue to build documentation on the PLC-5. Keep checking back for more information!

— Ricky Bryce