Introduction to Saving Energy in ControlLogix

We all like to save money, and there are always a few tweaks you can do to your project for saving energy in ControlLogix.

One of the simplest examples is lighting. When a light has been left on, shut it off after a certain amount of time. Additionally, shut down motors and cooling systems when practical. In this example, we will simply shut off a hydraulic pump if no valves have been moved on a system for 15 minutes.

Keep in mind that this example will not work for every situation. You will need to adapt any examples to your own application. Keep in mind any safety concerns de-energizing any part of your equipment for energy savings. Some parts of your equipment could “drift” when power is removed causing immediate movement back into place when power is re-applied. An example of this is a gate that we hold up with hydraulic pressure. If hydraulic pressure is removed, the gate might drift downward. When hydraulic pressure is re-applied, the gate could immediately go back into place.

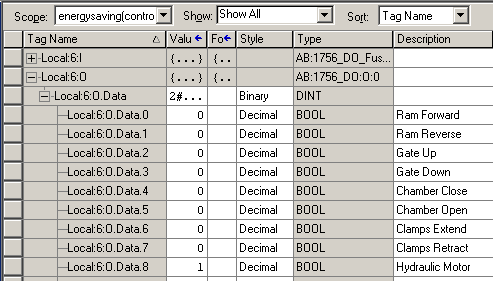

Our Existing Tags

In this example, assume that all valves are connected to a single output module. (If this is not true in your case, simply modify the logic to reflect your system)

As an illustration, here are our output tags for the valves:

Energy Saving Logic

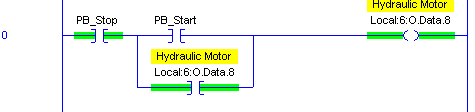

With this in mind, start with a simple rung to control the hydraulic motor:

In this case, when PB_Start is pressed, the Hydraulic motor energizes. The Stop button breaks the seal. The project has other logic to control all of the valves, but we are not concerned about that in this post. We will simply shut off the hydraulic pump after 15 minutes if no valves move.

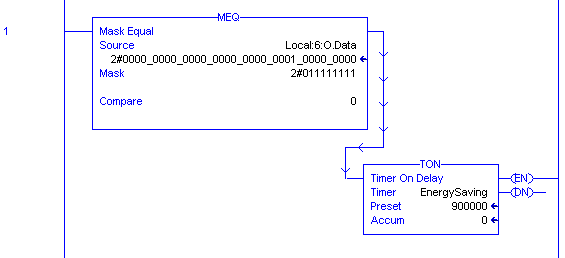

First, I’m going to add the following rung of logic. Our problem is that the Hydraulic motor is on the same output module as the valves. We need to mask out the Hydraulic Motor, because we only want to know the condition of the valves.

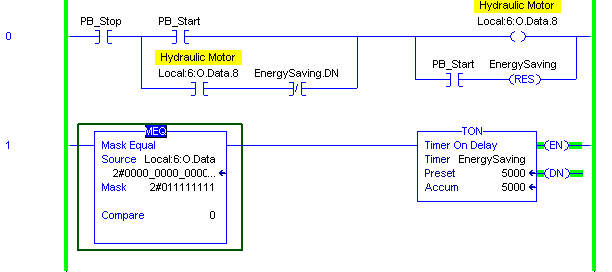

Through the mask, if the all of the outputs on the module equal Zero, then start an energy saving timer. I set the Mask value to 2#011111111. The mask tells the MEQ what bits to compare to Zero. Therefore, if all of the valves, (not the hydraulic pump) equal zero, then a timer will start to run. After 15 minutes, the EnergySaving.DN bit will go true.

Finally, we will modify the rung that controls the Hydraulic pump. Simply make the timer’s (NOT DONE) a condition that is required for the pump to remain sealed in. However, if the operator manually starts the Hydraulic pump, we want to reset our Energy Saving timer, so the pump will run for another 15 minutes. Keep in mind that when any valves move, the timer’s accumulated value also goes back to 0.

Visit the ControlLogix Category page for more examples!

— Ricky Bryce