Introduction to FactoryTalk View Training

The FactoryTalk View Training course will take about 4 days to complete. The training includes communication to the processor, and display screen objects. Additionally, we will discuss trending, parameters, and data logs. Students will also learn how to set up and troubleshoot alarms. By the end of the training, students will be able to create a new FactoryTalk View project from scratch. They will also be able to modify an existing project, and troubleshoot systems that use FactoryTalk View software. It’s your choice to use FactoryTalk View ME, or FactoryTalk View SE during the course of the training.

Communication

Students will learn how to configure communication to the processor (or multiple processors). Basically, in FactoryTalk Linx, we will create a communication shortcut. This shortcut represents the path to your processor. After that, the communication shortcut will be used on almost all objects on your display. Students will learn the difference between the development path, and the runtime path in FactoryTalk View ME. Basically, the development path is the communication path that FactoryTalk View uses as you build your project. The runtime path is how FactoryTalk View communicates to your PLC once you deploy your project.

Display Navigation

In most projects, it’s impossible to place all of your objects on a single display. Students will learn how to create additional displays. At the same time, we will configure navigation buttons that allow the operator to navigate between the displays. They will also learn how to declare an initial display at startup in FactoryTalk View ME. If you choose to use FactoryTalk View SE, we will create a startup macro. This startup macro will configure your initial displays when the project starts.

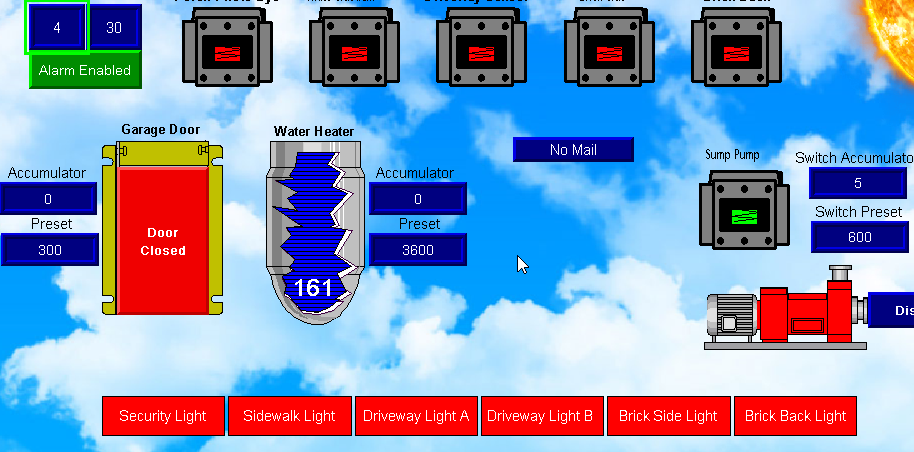

Basic Objects

Anything we add to a display is called an object. Students will add basic objects to displays such as push buttons. They will learn how to configure these buttons to write to a memory location in the processor. Likewise, we will cover output type objects. This includes simple line drawing objects, or objects from the graphics library. They will learn how to animate the objects. This animation will represent the state of a bit in the processor’s memory.

Numeric Objects

Numeric objects display or write values to the processor. In this course, we will cover numeric displays. Numeric displays will show a numeric value in the processor’s memory. For example, we can display temperatures or pressures. Likewise, we will cover numeric inputs. This allows the operator to enter a numeric value into an object. FactoryTalk view sends this value directly to a tag in the processor’s memory.

Advanced Numeric Objects

Numeric displays simply display the value of a tag. However, objects such as bar graphs and gauges will graphically show the normal operating ranges of these values. In addition to the bar graphs and gauges, students will learn to set up numeric sliders. This is a way for the operator to graphically enter a numeric value into the processor. The advantage of the slider is that the operator has a better sense of the allowable range of the input.

Global Objects

Global objects save time and memory by allowing you to create a grouped object that you will use over and over in your project. We simply build the global object one time. After that, we will reuse the object throughout your project. We simply a assign a different tag to each instance of this global object.

Trends and Data Logs

Trending will graphically show the value of a tag over time. This is useful for troubleshooting a system, and looking for patterns in value changes. When we couple the trend with a data log, the operator will also see a past history of tags. The data log has a history of the tags, and will display data that was recorded even when the trend chart was not active.

Parameters

Parameters are useful when you have many instances of the same object. For example, you might have multiple tanks. Parameters allow you to utilize the same display for multiple tanks. This reduces the number of displays to maintain. Likewise, it reduces the number of displays for licensing purposes. Students will learn how to create a single screen, and pass a different parameter file to this display based on the operator input.

Alarms

Alarms warn the operator of abnormal operation. For example, a bearing becomes too hot. The alarm server is running in the background of FactoryTalk View. When a tag exceeds a threshold value, the operator will see the alarm. We might use individual bits for an alarm as well. Students will learn how to set up and configure the alarm messages. Additionally, they will learn how to display a history of the alarms.

Security

Security continually becomes more important. This forces users to log into an application to access various displays. In class, we discuss how to add users to FactoryTalk View. We’ll configure security on various displays. Likewise students will learn how to hide objects on a display until the user logs in.

Summary

In summary, this is a good course for those who wish to learn programming and troubleshooting objects using FactoryTalk View. The course covers all of the basic features of the software. This includes setting up a project from scratch as well as using FactoryTalk View to troubleshoot problems such as unidentified alarm conditions. By the end of the course, students will have a working knowledge of how to set up and manipulate FactoryTalk View projects in your plant. We can do this course on-site for up to 10 students, or via WebEx.

For other information, visit the FactoryTalk view category page!

— Ricky Bryce