Introduction to Basic Customized Industrial Electronics Training

Basic Customized Industrial Electronics Training is important important for anyone who maintains electronic equipment in the industry. Maintenance personnel do not typically work on circuit boards at the component level anymore. However, this training will give your staff the ability to troubleshoot which circuit board has a failure. Additionally, students will learn how to filter noisy analog signals, and power sources. They will also learn about surge suppression to prevent certain failures. In many cases, this course will also give them the ability to innovate to keep equipment running until a new part arrives. This course removes additional unknowns from the troubleshooting process.

Resistance and Voltage Drops

Many intermittent failures in industrial automation are due to excessive voltage drops. Technicians usually underestimate the effect of these voltage drops on your system. This is especially true for lower voltage systems, such as 24v. For the same amount of power consumption, a device will need more amperage if it’s designed for lower voltages. This causes a higher voltage drop in your wiring system. Over time, you will add more devices to your equipment to improve it’s operation. If your technicians are not careful about how they supply power to these new devices, you could end up with frustrating intermittent failures. This is especially true for industrial networks which carry power along with the communication signal.

Capacitance

Capacitance can be your friend, or your enemy. This is good when we desire a constant voltage to equipment. However, this is very detrimental to industrial networks. Any time you have two conductors separated by an insulator, you have capacitance. With industrial networks, you need the signal to go from high to low (and vice-versa) very quickly. Too much capacitance will prevent this from happening, and force you to slow down the communication rate. Additionally, students need to be aware of the dangers of capacitance when they power off your equipment. Some capacitors may store up to 20kv. If they aren’t careful, they will feel more than just a “tingle” when working on this equipment.

Inductance

Just like capacitance, you need to be careful with inductance in your circuits. This is especially true for sensitive electronic equipment. Inductance will attempt to keep the current in a circuit the same. This is true regardless of what the voltage needs to go to in order to maintain that current. Inductive loads such as motor starters or solenoids are inductive loads. When we shut off these devices, they produce a voltage spike. Students will learn how to suppress this voltage spike so it does not get back into your sensitive electronic equipment, such as the PLC.

Transistors, Traics and MOSFETS (Customized Industrial Electronics Training)

You would expect every maintenance employee to understand how a relay works. Transistors are no different. Transistors act as switches to control a larger load with a small amount of current. We also use them for amplification. When replacing obsolete equipment, you may need to change the voltage level for your control circuit. At 2am, they can’t just run out and purchase a level converter. They will need to understand how to adapt and connect different types of equipment together. Triacs can act as a switch for AC, and MOSFETS can act as a high current switch for DC. Because of the high capacitance of the MOSFETS, though, students will need to understand how to drain the gate with a resistor to shut the circuit off.

High and Low Pass Filters

If you have noisy process variables (analog signals), then you may have excessive control action. This is due to the processor attempting to compensate for the apparent changes in the feedback from your process. Additionally, with networks, noise will cause errors on your network Another use for filtering is to convert PWM signals to true analog. In this section, students will learn to calculate the required components they need to pass certain frequencies, and suppress others. In the long run, you will save on maintenance costs, get better network speeds, and improve your departments ability to adapt to replacement equipment.

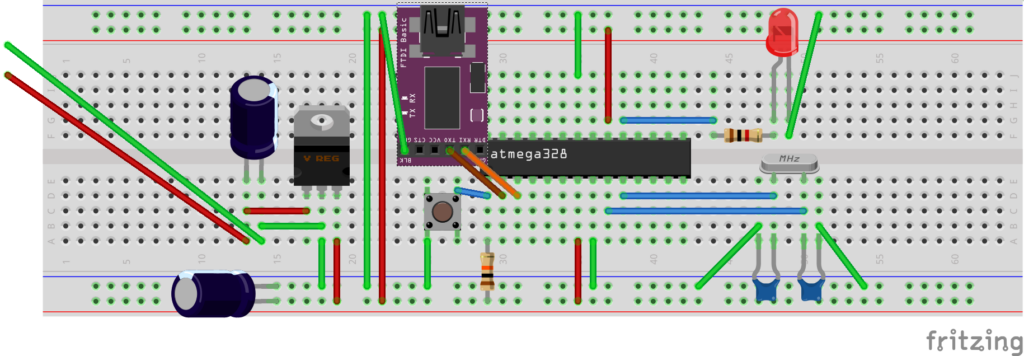

IC’s (Integrated Circuits)

This course will remove the intimidation of Integrated Circuits. Most maintenance personnel are intimidated by these components and think of them as “Computer Chips”. Although computers do use them, each pin of an IC has a particular purpose. We just need to know the IC’s pinout, which is available on it’s datasheet. Students will understand how to read the pinout and troubleshoot simple IC’s to determine if it’s performing it’s desired function. They will get comfortable utilizing various IC’s such as AND, OR, and NAND gates on a breadboard.

Industrial IC Controllers (PIC) (Optional)

Certain integrated circuits are programmable. That is to say, firmware is burned onto the IC. Occasionally, you may need to update this firmware. New firmware may have bug fixes, and additional features. Using the PICKIT, or EPROM burner, students will learn how to set the starting address for these binary files, and transfer the update onto the new IC.

Troubleshooting Circuits during Customized Industrial Electronics Training

By the end of this course, students will be able to assemble simple circuits using all of the above components. After that, the instructor will inject various faults into their circuits. This allows the students to look at a circuit from a troubleshooting point of view. Additionally, it requires them to use all of the skills they obtain earlier in the course.

— Ricky Bryce