Introduction to Old School ControlLogix Training

In today’s world, it’s hard to find Old School ControlLogix Training. Most modern training companies simply teach a canned course. Sometimes, they are even afraid to use proper terminology. Many modern instructors do not call on individual students in class to ensure everyone is participating and learning. They are taught that calling in students to ensure participation creates a “threatening” environment. It’s important that the instructor keeps everyone participating in the class. Equally important is that the instructor truly has the highest respect for each person in the class.

On the other hand, I’ve found out that the “Socratic” method of training is very effective. Students will pay more attention to the course material. Likewise, it shows the instructor the knowledge level of each student. This allows the instructor to make adjustments during the class to make sure no one is getting “lost” in the class.

ControlLogix training is progressive. In other words, the class builds on knowledge we gain in the class. For this reason, it’s very important that every student has a good conceptual knowledge of each topic. Additionally, it’s important that the instructors use your own plant systems as examples. That way, the students will understand how everything they learn in class applies directly to what they need to know.

The Purpose of ControlLogix Training

The purpose of ControlLogix Training is not to teach the students how to program. The purpose is to gain an understanding of your entire system for troubleshooting. Once students have a knowledge of how your entire system works together, they can utilize the status lights, and Studio 5000 for troubleshooting. Emphatically, most students will not be programming. They will simply be using Studio 5000 (RSLogix) as a troubleshooting tool. Generally, they will not be making changes to the program.

ControlLogix Hardware

Obviously, some students may have never seen a ControlLogix system before. It’s important to start at the ground and work upwards. The hardware is something they can physically put their hands on. A good instructor will tie the classroom instruction with previous knowledge the students have.

For example, the indicator lights on the input module are just like a voltage tester they use to troubleshoot a vehicle. The status lights simply tell us when we have a voltage or not. Conversely, the status lights on the output module, just tell us when the processor is trying to shut a switch within the output module. This just passes the power your supply to the output module to the field device.

We’ll use your own plant schematics, so the students understand how the field devices connect to these modules.

Additionally, we’ll discuss the processor status lights, and the purpose of the power supply. When an entire system is down, the first thing I always check is the system’s status lights.

ControlLogix Communications

Once the students learn the hardware, they will understand how to communicate to the processor from a PC. When I worked in tech support, probably 50% of the questions were related to communications.

If an employee does not understand communication, they will spend a lot of unnecessary time simply trying to get online from Studio 5000. Downtime is expensive. If a troubleshooter gets hung up on simple steps, the process of troubleshooting can turn into hours instead of minutes.

Basic Instructions

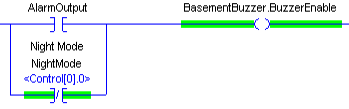

Basic instructions, such as XIO, XIC, and OTE, are basic foundations on which we build an understanding of how ladder logic works. We can customize the class to include function blocks if you use that as well.

Once they understand the flow of ladder logic, they will understand how some of the more complex instructions are activated, such as timers and counters.

Timers, Counters, and Analog

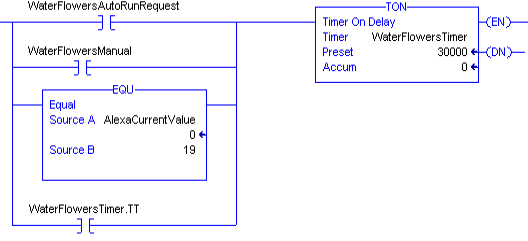

ControlLogix supports three types of timers: On Delay, Off Delay, and Retentive timers. Basically these timers work much like a hardware timer would. In fact, the ladder logic emulates the wiring of these timers very well. Students will understand how to use the members of the timer, such as the Done bit, Timer Timing bit, and Enable bit. We use timers in many programs.

Counters will count rung transitions. Typically, they keep track of a product count, machine starts, etc. Furthermore, you can use them for troubleshooting. Imagine a machine with 5 safety gates. One of these gates have an intermittent connection, but we don’t know which one. The troubleshooter can simply put a counter on each of these safety gates. The next time the problem occurs, they can simply see which counter incremented, and they will know where the problem is.

Much of the equipment in industrial automation contains analog inputs and outputs. These are variable voltage or current levels. Analog inputs read the STATUS of analog sensors such as temperature and pressure. On the other hand, analog outputs will CONTROL field devices such as control valves, or motor speeds. Typically, these analog values we be SCALED into engineering units before being used in other parts of the program, such as PID control. Students will understand the flow of information, and how to trace an analog signal back to the field device when a failure occurs.

Troubleshooting a ControlLogix System

Once the students have a good understanding of how ControlLogix works, they will put their skills to work. We will use your own plant programs to locate outputs, and navigate through your program. We will trace down several field devices as examples. Once they are comfortable in your own programs, we’ll give them exercises on the training station to re-enforce that knowledge. This includes using the Bookmark system, Cross-Referencing, Searching, and the “Browse Logic” feature in Studio 5000.

Summary of Old School ControlLogix Training

In short, time is money. Even more important is safety. For this reason, it’s important for students to understand how every component of your system works together. If there is any part of the system that is unknown, then the amount of downtime will can become astronomical. Proper ControlLogix Training will give the students a complete conceptual knowledge of your own equipment. Obviously, this will improve safety, and decrease downtime.

For more information on ControlLogix, visit the category page!

— Ricky Bryce