ControlLogix While / Do Statement

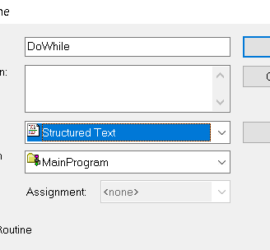

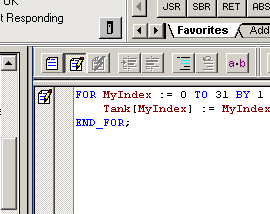

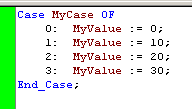

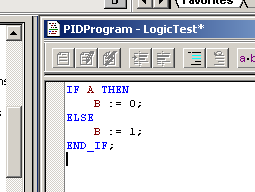

Introduction to the ControlLogix While / Do Statement The ControlLogix While / Do Statement allows you to execute a block of code while a specific condition is true. This statement is available in Structured text. You can use this statement to perform large calculations on arrays. Some vendors might use Read More »